Historic renovation requirements

A 100-year-old moulding style may not be manufactured any more. We can make it! We can match any moulding profile to exacting standards of historical accuracy. We have an archive of over 2000 knives; if none of these knives work, we’ll have a knife specially ground to replicate the profile you need.

Local unavailability

An architect might specify a profile that’s unavailable in our area. It takes less time for us to custom-craft it rather than tracking it down and having it shipped… and it’s often less expensive as well.

Client desire for uniqueness

Some clients want moulding that’s absolutely one-of-a-kind. Tell us what you’d like, and we’ll make it for you.

Special moulding applications

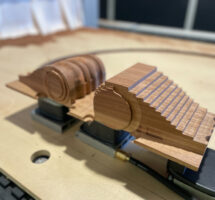

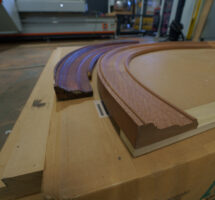

Custom moulding is the perfect solution to unusually shaped surfaces, particularly curved applications. We can make all sorts of radius moulding – like crown, base, chair rail, jambs, window surrounds – to fit any convex or concave shape.

Custom materials

Most stock moulding is made from paint- or stain-grade pine, fir, or oak. The Tague Custom Moulding Division creates any profile in any hardwood, such as Spanish cedar, poplar, Sapele mahogany, red oak, white oak, birch, black locust, cherry, maple, walnut… or any wood species a customer requests. We can also craft mouldings from MDF and PVC (Kleer).

Economy of scale

If you’re designing or building a high-end residence or commercial space, you might find that going custom for all the moulding the job requires does not cost much more than assembling various types of stock moulding. With custom moulding, you get a distinctive look that delivers a lot of bang for your buck!

3-D Printed Custom Moulding Samples

If you only need a small sample (4 inches or less) of a custom moulding profile, our enhanced 3-D printing capabilities now allow us to offer custom moulding samples. For a small fee, your custom sample will be a full-scale 4 inch (approx.) rendition of the moulding profile you select. Current turn around for custom samples is approximately one week.

If you’re in the market for historic or custom mouldings, please see our Custom Millwork Services page to learn more about this service. We can also curve and bend historic and custom mouldings. To learn more, please see our Curved & Radius Mouldings and Jambs page.