- Home

- Moulding Guide

- Lumber & Building Products

- Building Materials

- Commercial Building Products

- Decking & Outdoor Materials

- Doors

- Green Building Practices

- Builder’s Hardware Supplier

- Kitchen and Bath Design

- Moulding & Millwork

- Siding, Roofing & Flooring

- Windows and Shutters

- Custom Millwork Division

- Tague Design Showrooms

- Kitchen & Bath

- Tague Architectural

- Premier Commercial Door, Frame & Hardware

- Locations

- Careers

- Blog

- Events

- About

- Services

- Literature

- Newsletter

- Contact

- Request a Quote

- Moulding Guide

- Lumber & Building Products

- Custom Millwork Division

- Tague Design Showrooms

- Kitchen & Bath

- Tague Architectural

- Premier Commercial DFH

- Locations

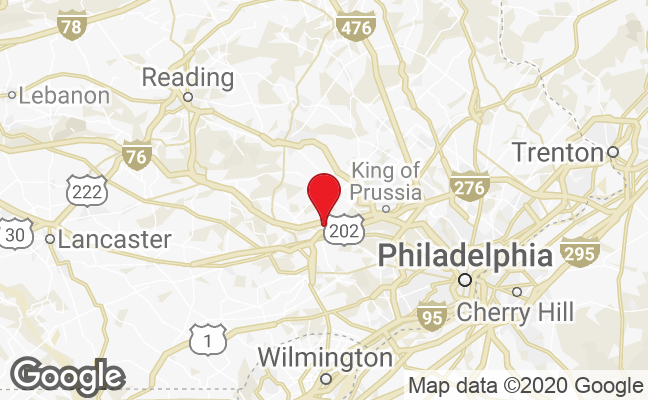

The Tague Lumber Custom Millwork Division offers builders, contractors, architects, designers, remodelers, and discerning homeowners the flexibility of custom millwork solutions when a suitable product cannot be sourced from a manufacturer. Simply put, if Tague can't buy what you want, we'll make it for you – right here in Chester County, Pennsylvania.

Learn more

The Tague Lumber Custom Millwork Division prides itself on excellent service. Initial consults are always free. Every job includes, at no additional charge:

• Estimates

• Site Measuring and Templating

• Take-offs

• Shop Drawings

• Delivery

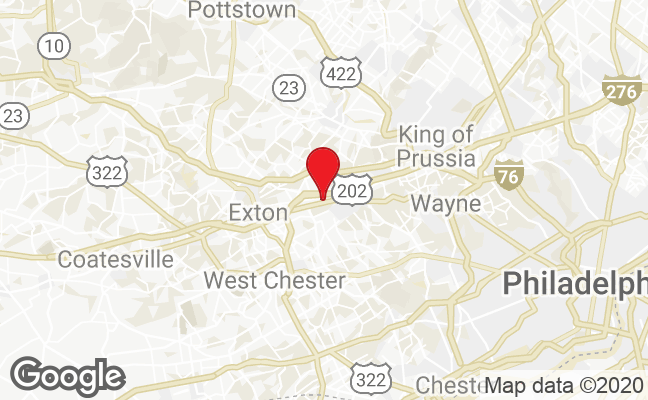

Address: 181 Lancaster Ave, Malvern, PA 19355

Phone: 610.640.4180

Fax: 610.640.4240

Email: malvern@taguelumber.com

The Tague Design Showroom in Malvern, Pennsylvania opened in 2009. With this facility, we hoped to bring to homeowners, architects, and designers the superior levels of selection and service we've provided to our contractor and builder clientele for over a century. Learn more

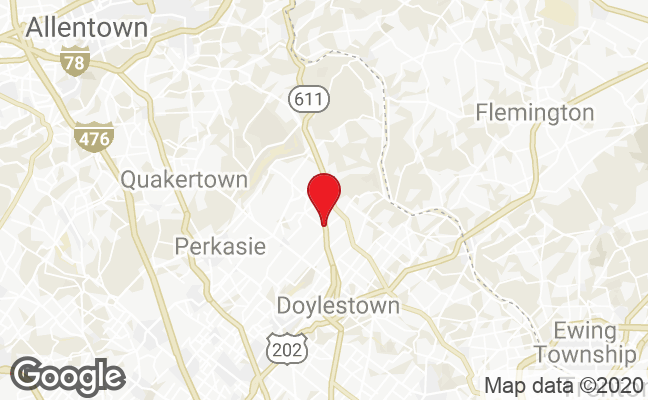

Tague Lumber opened our second showroom at our Doylestown location in 2017. The 3,500-square-foot facility features beautiful displays of windows, doors, kitchen cabinetry, mouldings, hardware and more on the same site as one of our working lumberyards. Learn more

Premier Commercial Door, Frame & Hardware – a division of Tague Lumber – specializes in hollow metal and wood doors for commercial construction. With our on-site welding and fabrication capacity, we can supply you with doors and frames for any job, big or small. We are also distributors for top lines of commercial hardware, as well as for washroom partitions and accessories. If we don't have what you need in stock, or we can't make it, we'll order it for you and get it delivered to your worksite...

Learn more

-

Doylestown / Plumsteadville

6100 Easton Rd, PO Box 751, Plumsteadville, PA 18949

215-348-9408 -

Kennett Square

475 McFarlan Rd, Kennett Square, PA 19348

610-444-1200 -

Media

325 Media Station Rd, Media, PA 19063

610-566-1200 -

Philadelphia

560 East High St, Philadelphia, PA 19144

215-848-2500 -

Phoenixville

405 Bridge St, Phoenixville, PA 19460

610-933-5858 -

Premier Commercial Door, Frame & Hardware

7 Lee Blvd, Malvern, PA 19355

215-673-0700 -

Tague Design Showroom, Malvern

181 Lancaster Ave, Malvern, PA 19355

610-640-4180 -

Out of State Orders

Contact TJ Vanleer, VP of Sales:

tvanleer@taguelumber.com

215-778-6463